Advanced Filters

Category

Subcategory

Condition

Slaghog for Plasma Cutting Tables

Featured

Introducing the new SLAGHOG™ for PLASMA (SHP) for difficult to remove slag on plasma and oxyfuel ...

Details

Rhino Hammer

Featured

The Rhino Hammer™ makes removing tabbed parts much easier after they are cut. It uses shop air to...

Details

Slaghog HD for Lasers 4kw-20kw

Featured

Increased torque motor quickly removes tougher slag and dross buildup from the slats on higher po...

Details

Slat Shield Plus (Spray Coating on Slats)

Featured

Slat Shield Plus comes in a 5 gallon container. It is a slag/dross preventative that can be appli...

Details

2025 Mitsubishi Mitsubishi Fast Bend Cell

In the highly competitive manufacturing landscape, the press brake industry faces significant cha...

Details

AKS Dura-Kut

Industrial Plasma Cutter Perfect for Large, Thick Plate Applications Looking for an industrial pl...

Details

AKS Plasmatic

Superior Quality Entry-Level Small Plasma Cutter If you’re seeking a high-quality entry-level sma...

Details

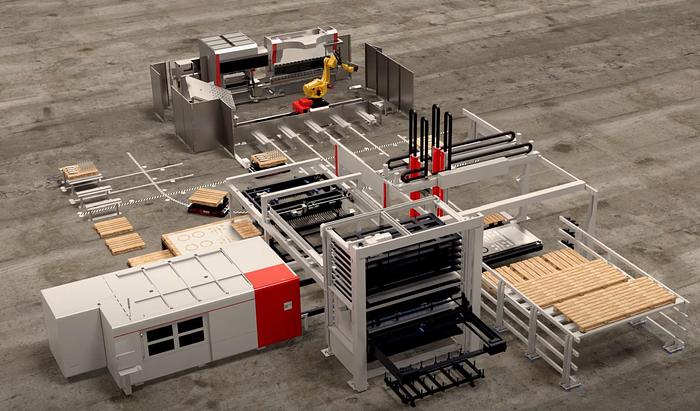

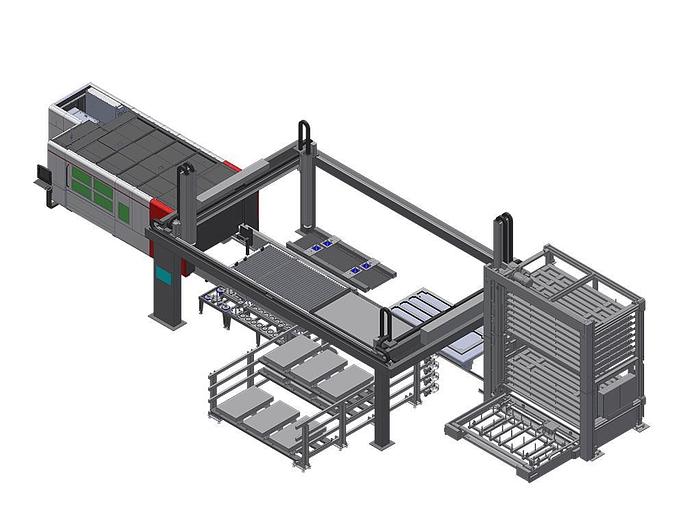

Mitsubishi Laser Blank - Part Sort - Bend Fabrication Cell

The Mitsubishi Total Fabrication Cell consists of one or more Mitsubishi Fiber Lasers, Material S...

Details

AKS Water-Kut X4

Premium Precision Waterjet Cutting Machine

Seeking a precision waterjet that delivers high accur...

Details

Muratec Motorum 30510 30 Ton Turret Punch

The M30510TG emerges as a game-changer in fabrication, introducing novel technology that elevates...

Details

Muratec Motorum 2048 20 Ton Turret Punch

The Motorum M2048TS is a servo-driven punch press, embodying Muratec’s renowned ram axis design f...

Details

Muratec Motorum 2548 25 Ton Turret Punch

Our 25-ton CNC punch presses feature servo-electric drive systems, combining efficient energy ope...

Details

AKS Accu-Kut

Streamline Operations with the Largest Unitized System on the Market When you need a durable, tru...

Details

2014 Lissmac SBM XL S2B2 1500

Used SBM XL S2B2 1500 has 2 Sand Block belts on the top and bottom in the first head to round edg...

Details

2023 Lissmac SBM L G1S2 1500

Gently used SBM L G1S2 1500 has 2 grinding belts in the first head to remove a vertical burr. It ...

Details

SMARTFLEX RAPID SERIES

Truly taking advantage of today’s faster lasers and improved software requires an automation solu...

Details

2011 Mitsubishi 3015 CO2 Laser EX-45 CFG

Certified Reconditioned Pre-Owned PHX Cutting Head 3 Month Factory Warranty Installation & Traini...

Details

2016 Mitsubishi 3015 Fiber Laser EX -FZ 6kw

Certified Reconiditoned Pre-Owned Zoom Cutting Head (M700) 3 Months Factory Warranty Installation...

Details

SMD 133 DRE

Single sided deburring, deslagging, and edge rounding. Get Started with FABCOR Machinery

Details

SBM-XL G2S2 1500

Double sided heavy deburring and light deslagging. Get Started with FABCOR Machinery

Details

Mitsubishi XL

The XL has the same high speed motion system as the XL-F fiber, with a unique beam delivery syste...

Details

Mitsubishi VZ Series

Access to the cutting table is vital for throughput on a short run 3D laser for setting up fixtur...

Details

Mitsubishi HVII-R

Simple, powerful, accessible. If you’re looking for a short-run laser check out the HVII-R, the l...

Details

Mitsubishi CO₂ Resonator

Mitsubishi’s patented resonator is the heart of all of its CO2 lasers. The unique cross-flow desi...

Details

VZ20 3D Laser

Delivering unparalleled utility, flexibility, and working speeds while being easier and less cost...

Details

SMARTFLEX COMPACT TOWER

The Compact Tower system is available in a number of configurations, meaning our automation can e...

Details

SMARTFLEX ELEMENT TYPE R

Laser Automation is crucial in a high-production fabrication environment. Mitsubishi designed the...

Details

SMARTFLEX RIVER SYSTEM

SMARTFLEX RIVER SYSTEM An automation solution with virtually unlimited storage capacity, the Rive...

Details

ELEMENT TYPE R BASE

The SmartFlex Element Type R boosts production while maintaining unrestricted access to the laser...

Details

SMARTFLEX COMPACT PLUS

A streamlined operation is flexible as well as fast, and the Compact Plus automation system provi...

Details

SMARTFLEX COMPACT PLUS LOAD/UNLOAD

The Compact base is a purpose-built load/unload with full 1” thickness capability within a 32’x36...

Details

SMARTFLEX RAPID TOWER

The Rapid tower is Mitsubishi’s most popular automation configuration. Most owners go on to add a...

Details

ASTES4 SYSTEMS

Mitsubishi’s partnership with Astes4 is pushing laser automation to provide more functionality wi...

Details

SMARTFLEX RAPID BASE LOAD/UNLOAD

The Rapid Base features two independent over-under shuttle carts for raw material, and two for co...

Details

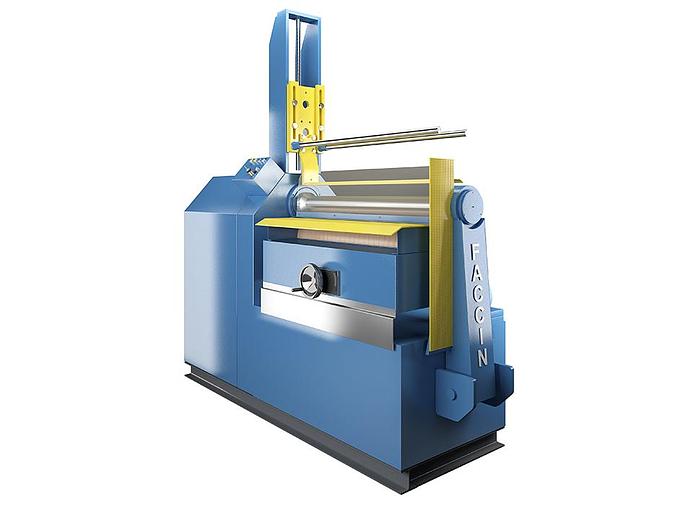

Faccin 2 Roll Bending Machine HCU

The HCU version 2-roll bending roll designed, built and marketed by Faccin features a special con...

Details

Faccin 3 Roll Bending Machine 3 ASI

The initial pinch bending roll model of the ASI series is the best solution for bending plates wi...

Details

Faccin 3 Roll Bending Machine 3 HEL

Precise, reliable and powerful, the 3HEL series represents the latest evolution of the traditiona...

Details

Faccin 3 Roll Viarable Geometry Plate Bending HAV

High rolling power combined with maximum pre-bending precision: HAV is the series of 3-roll varia...

Details

Faccin 4 Roll Bending Machine Planetary 4HEP

The 4HEP series of 4-roll synchronized bending rolls is latest evolution of a design developed in...

Details

Faccin 4 Roll Bending Machine 4HEP-E

The NEW 4HEP-E is a 4-roll, direct electric-drive plate roll which provides unmatched efficiency,...

Details

VZ10 3D Laser

A seamless, effective way to automatically manage and maximize your machinery investment. Featuri...

Details

Acieta Mitsubishi Automated Robotic Press Brake Cell

RIBS, or Robotically Integrated Bending Solutions, offer significant cost and productivity benefi...

Details

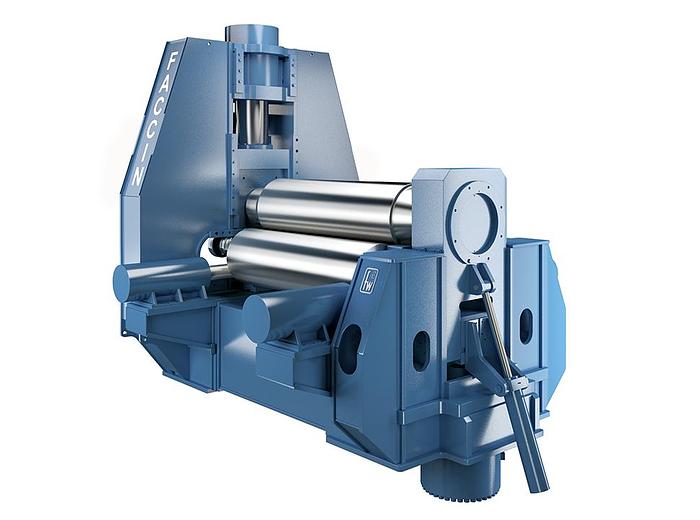

Faccin 4 Roll Bending Machine 4HEL

4HEL is the most precise and easiest to use series of 4-roll plate bending machines with total pr...

Details

Mitsubishi eX Plus

The industry’s best selling 5’ x 10’ CO2 is now even better; all the attractions of the eX, plus ...

Details

Roundo Flanging Machine

SF is our range of patented machines for the production of flanged and punched cylinders. Almost ...

Details

GX-F Advanced Series

The GX-F Advanced pairs increased power, 4kw – 20kw, with the capabilities of machine learning. A...

Details

SBM-XS G1E1 300

Double sided small part deburring and edge rounding. Get Started with FABCOR Machinery

Details

Diamond BB

The all-electric Diamond BB series of brakes uses an AC Servo motor and ball screw drive that boo...

Details

Roundo Section Roll

With the largest selection on the market, ROUNDO is the leading manufacturer of section bending m...

Details

Diamond BH

Mitsubishi believes finding the right press brake for your shop shouldn’t be about compromise. Tr...

Details

GX-F Series

The GX-F Series features intuitive M800 controls, and an update to the revolutionary ZOOM head wi...

Details

Boldrini Straightening Machine

BOLDRINI’S Plate Straightening Machine can work plates up to 4500mm width and 90mm of thickness w...

Details

Diamond BH ATC

Pairing a Diamond BH series Brake with ATC automation frees up operators to work more efficiently...

Details

Mitsubishi XL-F

Mitsubishi’s largest fiber features a 20’ or 26’ long table and several automation options. A 10’...

Details

Boldrini Dishing Press

Heads of any size can be manufactured with our Portal Frame Presses which range from 150 to 5000 ...

Details

Adira Hydraulic Press Brakes

MC press brakes partnered with Adira to provide an equipment solution for jobs requiring high ton...

Details

Boldrini Flanging Machines

The vast majority of large dished and flanged ends produced in the world today are manufactured w...

Details

Mitsubishi FV 5-AXIS SERIES

The new Mitsubishi FV fiber laser uses an innovative double-rail gantry motion system for high-sp...

Details

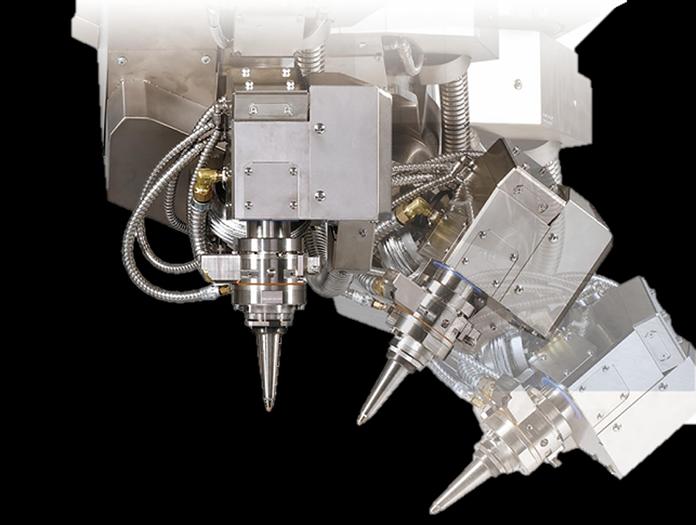

Mitsubishi Zoom Head

Mitsubishi’s ground-breaking Zoom head automatically sets optimal beam diameter, focal length, an...

Details

Boldrini Section Roll

BOLDRINI’S initial expertise was in developing technology to provide this type of machine, capabl...

Details

MP FLEX Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

LCG 3015 6K Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

LCG 3015 Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

LC 4020 F1 NT Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

LC 4020 F1 NT Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

FOL 3015 AJ Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

FO MII 3015 Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

FO 3015 II NT Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

FLC 3015 AJ Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

FLC 3015 AJ Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

FLC 3015 AJ Copper Slat

We produce copper slats for use on all major laser manufacturers.

Copper slats can be produced t...

Details

HE&M Saw WF 190 MRB

The WF190MRB-DC is a powered double-miter band saw operated using a touch screen mounted in a ped...

Details

HE&M Saw WF 190A

The WF190A Smart Saw includes a touch screen control mounted in a swing away console. The multi-i...

Details

HE&M Saw DC 5353

The DC5353 is operated using a touch screen control in a pedestal mounted console and can be oper...

Details

HE&M Saw H3236A-DC

The H3236A-DC band saw operates using a touch screen control mounted in a swing-away console. A 4...

Details

HE&M Saw H3226M-DC

The H3236M-DC is operated using a touch screen control mounted in a swing-away console and can be...

Details

HE&M Saw H260A-DC

The H260-DC band saw operates using a touch screen control mounted in a swing-away console. A 48”...

Details

HE&M Saw H260M-DC

The H260M-DC operates using touch screen mounted in a swing-away console. The patented Cut Watche...

Details

HE&M Saw DC22A

The DC22A band saw operates using a touch screen control mounted in a swing-away console. A 48” s...

Details

HE&M Saw DC22

The DC22M band saw is operated using a touch screen that is mounted in a swing-away console. A fu...

Details

HE&M Saw H130A-DC

The H130A-DC uses a touch screen control and allows job programming and retains jobs for later us...

Details

HE&M Saw H130-DC

The H130-DC Saw Series is an established tried-and-true performer that has been around for many y...

Details

HE&M Saw V360M

The V360M is a large capacity non-mitering vertical band saw designed to cut large blocks or bill...

Details

HE&M Saw V750M

The V750M is a large capacity non-mitering vertical band saw designed to cut large blocks or bill...

Details

HE&M Saw VT 100LM-45

The VT100LM-45 will miter up to 45ᵒ in both directions. A self-contained hydraulic system powers ...

Details

HE&M Saw VT 100HLA-60-CTS

The VT100HLA-60-CTS is a fully automatic and programmable saw that will miter up to 60ᵒ in both d...

Details

HE&M Saw VT 100HLM-60-CTS

Swing-Away Control Console w/ 7" Touch Screen 4° Removable Arm Cant Powered Programmable Tilt w/ ...

Details

HE&M Saw VT 100LM-60

The VT100LM-60 will miter up to 60ᵒ in both directions. A self-contained hydraulic system powers ...

Details

HE&M Saw 260 BSA

The 260 is a double-mitering band saw cutting 45ᵒin both directions, up to 60ᵒ left miter, includ...

Details

HE&M Saw 320 BSA

The 320 BSA is a double-mitering band saw cutting 45ᵒin both directions, up to 60ᵒ left miter. Th...

Details

HE&M Saw 450 BSA

The 450 BSA is a double-mitering band saw cutting 45ᵒin both directions, up to 60ᵒ left miter. Ad...

Details

HE&M Saw Hurricane 2030A-CTS

The Hurricane 2030A-CTS band saw allows programmable miter cuts up to 60ᵒ in one direction. A tou...

Details

HE&M Saw Cyclone A-C

The Cyclone A-C multiple indexes with a 24” bar-feed, saves up to 99 jobs, sawing one job or mult...

Details

HE&M Saw Cyclone A-4

The Cyclone A-4 makes cutting 45ᵒ miter cuts in one direction perfect for cutting small solids an...

Details

HE&M Saw Cyclone M

The Cyclone M miters to 60ᵒ one direction, is ideal for cutting solids and structural shapes with...

Details

HE&M Saw H130A

The H130A is known for rugged and dependable band sawing. The 10 HP motor powers the 1½” blade an...

Details

HE&M Saw H130M

The H130M is a rugged band saw and cuts using a 1½” blade driven by a 10 HP motor. A 2 HP hydraul...

Details

HE&M Saw H105A-C

The H105A-C includes a 24” bar-feed and allows multiple indexes and the ability to create and sav...

Details

HE&M Saw H105A-4

The H105A-4 model includes a 7½ HP motor and a 1¼” blade with a 24” stroke bar-feed that will ind...

Details

HE&M Saw H90A-C

The H90A-C includes a 24” bar-feed, allows multiple indexes, and the ability to create and save u...

Details

HE&M Saw H90A-4

The H90A-4 offers up to 4 indexes 24” each and will cut up to 999 same-length parts. The H90A-4 g...

Details

AKS Tru-Kut

The Industry Standard for Precision CNC Plasma Cutters When you need a cost-effective, precise CN...

Details

AKS Water-Kut X3

Superior Waterjet Machine with Ultimate Performance The water-kut x3 combines maximum performance...

Details

AKS Water-Kut X2

High-Precision Waterjet with a Smaller Footprint Need a small waterjet for your operations? Look ...

Details

HE&M Saw H90A-1

The H90A-1 offers accurate cuts on small solids and shapes. It is perfect for cutting multiple pa...

Details

HE&M Saw H105-M

The H105M model includes a 7½ HP motor and a 1¼” blade and will produce straight cuts fast. This ...

Details

Muratec Motorum 50 Ton Turret Magnum 5000

The Magnum M5000 is a robust mechanical CNC turret punch press delivering 50 tons of punching for...

Details

Muratec Motorum 3058 30 Ton Turret Punch

The M3058TG is a testament to environmental consciousness and power efficiency, operating with en...

Details

Muratec Motorum 3048 30 Ton Turret Punch

The M3048TG stands as a testament to our ongoing innovation in punch press technology. This servo...

Details

Muratec Motorum 2558 25 Ton Turret Punch

Equipped with a servo-electric punch drive system, the M2558TS excels in high-speed production wi...

Details

Muratec Motorum 2024 20 Ton Turret Punch

In a groundbreaking step for punch press technology, MURATEC introduced a pioneering concept in 1...

Details

Acieta Weld Cell

Manufacturers that are positioning for growth are planning for automation. The challenge with ado...

Details

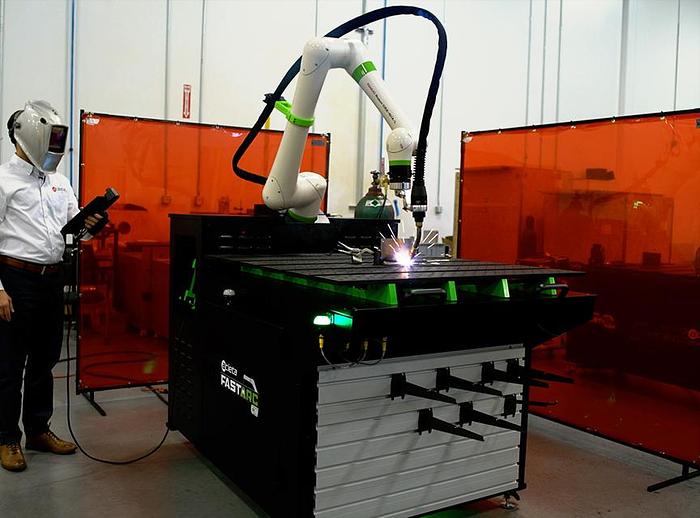

Acieta Fast ARC CX1000

Are you challenged with finding good welders; or even worse, challenged with having your extremel...

Details

Acieta Fast Arc Cobot

Skilled welders are a hot commodity, and production lines sit idle while companies struggle to fi...

Details

AKS Plasmatic Pro

Exceptional Entry-Level Plasma Cutting Starts Here Designed as an upgraded version of the acclaim...

Details